Elevator conveyor belts are an essential component in the manufacturing and transportation industries. They are responsible for moving heavy loads from one level to another, making the process more efficient and less labor-intensive. Chances are you have encountered an elevator conveyor belt of companies like Bi State Rubber in your line of work. But have you ever wondered how they work? In this comprehensive guide, we will delve deep into the workings of elevator conveyor belts. We will also explore the technology that makes them an indispensable part of modern industry.

Types of Elevator Conveyor Belts

There are three main types of elevator conveyor belt:

- Steel Cord Belt

Steel cord belts are made up of stainless steel cords embedded in a rubber belt. These belts are highly durable and can withstand heavy loads and harsh environments.

- Textile Belt

Textile belts are made up of multiple layers of fabric, usually polyester or nylon, and rubber. These belts are more flexible than steel cord belts. These are often used in industries such as agriculture and food processing.

- Bucket Belt

Bucket belts consist of buckets that are attached to a textile or steel cord belt. These buckets are used to transport bulk materials such as grain, cement, and ore.

Parts of Elevator Conveyor Belts

Elevator conveyor belts consist of several key components:

- Belt

The belt is the main component of the conveyor and is responsible for transporting materials from one point to another. Elevator conveyor belts are usually made of rubber or PVC.

- Buckets

Buckets are attached to the belt and are responsible for carrying the materials. The size and shape of the buckets depend on the type of material being transported.

- Pulleys

Pulleys are responsible for guiding and supporting the belt. They are usually made of steel and are located at both ends of the conveyor.

- Drive Unit

The drive unit is responsible for powering the conveyor. It consists of an electric motor, gearbox, and couplings.

- Tensioning Device

The tensioning device is responsible for maintaining the proper tension on the belt. It is usually located at the end of the conveyor.

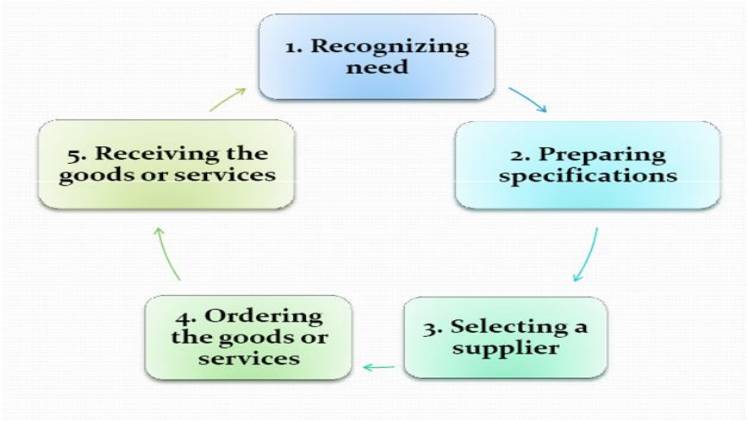

How Elevator Conveyor Belts Work

The operation of elevator conveyor belts can be broken down into five main components:

- The belt moves along the conveyor, carrying the materials from one point to another.

- The buckets are filled with materials and are carried along the belt.

- The pulleys guide and support the belt, ensuring that it moves along the conveyor without slipping or coming off the track.

- The drive unit powers the conveyor, providing the necessary force to move the belt and the buckets.

- The tensioning device ensures that the belt remains tight and does not slip or come off the track.

Safety Considerations for Elevator Conveyor Belts

When working with elevator conveyor belts, it is essential to consider safety. Some of the main safety considerations include:

- Hazardous Materials

If the materials being transported are hazardous, it is important to ensure that the conveyor is properly sealed to prevent leaks.

- Fire Hazards

Conveyor belts can generate heat and sparks, which can be a fire hazard. Proper ventilation and fire suppression systems should be in place to prevent fires.

- Maintenance Considerations

Regular maintenance is essential for ensuring the safe operation of elevator conveyor belts. Maintenance tasks should be carried out by trained professionals.

Maintenance and Troubleshooting of Elevator Conveyor Belts

To ensure the safe and efficient operation of elevator conveyor belts, it is essential to perform regular maintenance and troubleshooting tasks. Some of the main maintenance tasks include:

- Regular inspections should be carried out to identify any signs of wear or damage to the conveyor belt, buckets, pulleys, or other components.

- Proper lubrication is essential for preventing wear and tear on the conveyor components. Lubrication should be carried out according to the manufacturer’s recommendations.

- The tension of the conveyor belt should be adjusted regularly to ensure proper operation.

- The conveyor belt should be tracked to ensure that it is running smoothly and does not come off the track.

Conclusion

Elevator conveyor belts are a crucial component of many industries. They are designed to efficiently move materials vertically, saving time and labor costs. Understanding how these belts work is essential for proper maintenance and operation. By following the guidelines outlined in this comprehensive guide, businesses can ensure optimal performance and longevity of their elevator conveyor belts. Incorporating the right elevator conveyor belt system can help you streamline your operations. It will help you to increase productivity and ultimately improve your bottom line.